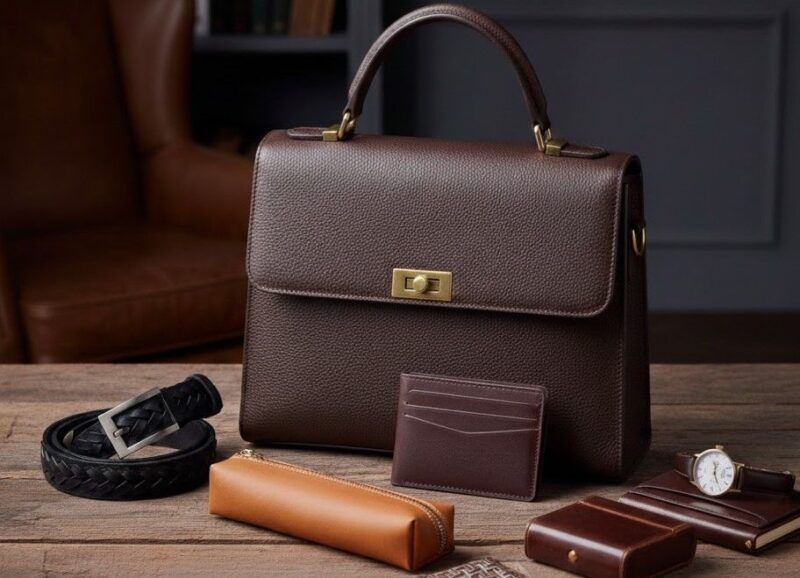

An accessory looks expensive when its proportions support real use, its structure keeps shape under stress, and its finish reflects controlled manufacturing rather than decoration.

Perceived value usually comes from engineering discipline, material stability, and production precision.

Price alone does not create a premium impression. Construction consistency, durability signals, and tactile quality do.

Proportion – Functional Scale Creates Visual Authority

Proportion determines whether an accessory looks intentional or mass-produced. Proper scale reflects real-world use conditions. A bag handle must distribute weight correctly. A wallet must hold contents without bulging.

A watch strap must balance the case size. When proportions match function, the accessory appears engineered rather than styled.

Large logos, oversized hardware, or excessive thickness often signal cost-saving design shortcuts. Manufacturers sometimes increase the size to compensate for weaker materials. This produces visual imbalance and reduces perceived quality.

Correct proportion also affects wear patterns. Accessories designed at a proper scale age more evenly because stress distributes predictably.

Proportion Factors That Influence Perceived Value

| Design Element | Premium Indicator | Cheap Appearance Trigger |

|---|---|---|

| Thickness | Supports function without bulk | Distortion or stiffness |

| Hardware scale | Balanced with body size | Oversized decorative metal |

| Edge profile | Smooth consistent contour | Uneven thickness |

| Carry dimensions | Practical capacity | Overstuffed silhouette |

| Strap length | Natural ergonomics | Awkward positioning |

Precision proportion often requires more development time, which is why lower-cost accessories frequently ignore it.

Structural Integrity – Shape Retention Signals Durability

Structure is the strongest non-material indicator of quality. Accessories that maintain their silhouette after repeated use appear expensive because they demonstrate fatigue resistance. Collapse, sagging, or deformation suggests weak reinforcement or thin materials.

Structured accessories rely on layered construction. Reinforcement panels, controlled stitching tension, internal frames, and balanced weight distribution all contribute to longevity.

Poor structure also affects usability. Bags that collapse become difficult to access. Wallets that warp strain seams. Sunglass cases without rigidity fail to protect lenses. Structural stability, therefore, affects both perception and function.

Structural Construction Elements

| Structural Feature | Practical Effect | Perception Impact |

|---|---|---|

| Reinforced seams | Prevent stretching | Reliability signal |

| Multi-layer panels | Increased durability | Solid feel |

| Edge reinforcement | Shape retention | Clean outline |

| Internal supports | Stress distribution | Professional finish |

| Balanced weight design | Comfortable handling | Quality impression |

Structure often matters more than material category. A well-constructed synthetic accessory can appear more premium thana poorly assembled natural leather.

Manufacturers focused on construction discipline often emphasize proportion and structural precision over decorative elements.

That approach is visible in product lines like Grainmark Leather, where controlled proportions, stable silhouettes, and refined finishing techniques illustrate how durability-driven design influences perceived value.

The emphasis remains on usability rather than visual excess, which typically aligns with higher-end accessory perception.

Finish Quality – Precision That People Notice Immediately

Finish is the most visible indicator of manufacturing care. It includes edge sealing, stitching regularity, surface treatment, hardware alignment, and material transitions. Imperfections in the finish are detected quickly, even by non-experts.

Consistent stitching spacing signals calibrated machinery or skilled manual work. Clean edge finishing prevents fraying and moisture intrusion. Surface consistency indicates controlled dye or coating processes.

Finish quality also influences aging. Well-finished accessories develop gradual patina rather than abrupt deterioration.

Finish Elements That Raise Perceived Quality

| Finish Detail | Quality Signal |

|---|---|

| Edge sealing or burnishing | Prevents wear and moisture |

| Stitch symmetry | Manufacturing precision |

| Hardware alignment | Mechanical accuracy |

| Surface consistency | Controlled material treatment |

| Color uniformity | Stable dye processes |

Finish mistakes typically reveal rushed production.

Material Stability And Performance Over Time

Material quality contributes to premium perception primarily through stability. Materials that resist cracking, fading, stretching, or peeling maintain visual integrity longer.

Leather thickness consistency, textile weave density, metal alloy stability, and polymer flexibility all influence long-term appearance. Accessories made from unstable materials quickly lose perceived value, even if initially attractive.

Performance indicators include:

|

Stable materials support structural integrity and finish longevity.

Hardware Precision And Mechanical Reliability

Hardware often determines daily usability. Zippers, buckles, clasps, hinges, and rings experience repeated mechanical stress. Precision manufacturing prevents friction, noise, and misalignment.

Premium hardware typically features smoother actuation, consistent plating, tighter tolerances, and better weight balance.

Hardware Quality Indicators

| Hardware Component | Premium Characteristic | Poor Quality Sign |

|---|---|---|

| Zipper mechanism | Smooth silent motion | Catching or rattling |

| Buckles | Balanced weight | Hollow feel |

| Clasps | Firm closure tension | Loose fit |

| Rings and loops | Seamless joints | Visible weld marks |

| Metal finish | Even plating | Flaking or discoloration |

Mechanical reliability reinforces perception of thoughtful engineering.

Color Control And Visual Consistency

Color management significantly affects perceived expense. Uniform dye penetration, consistent tone across panels, and matching edges indicate controlled production.

Uneven coloration usually results from rushed finishing or inconsistent materials. Accessories that age evenly often appear higher quality because the visual change looks intentional rather than defective.

Controlled matte finishes frequently look more premium than high gloss because they emphasize material authenticity over coating thickness.

Tactile Feedback And Weight Distribution

Touch perception strongly influences perceived value. Materials that feel stable, balanced, and comfortable communicate durability.

Weight alone does not signal quality. Balanced weight distribution matters more. Accessories that feel heavy but poorly balanced appear inefficient rather than premium.

Tactile cues include:

|

These sensory signals shape subconscious judgments.

Design Discipline And Minimalism

Accessories that look expensive often show restraint. Clean lines allow structural and finish quality to dominate visual perception. Excess ornamentation frequently masks structural weaknesses.

Minimal design does not mean plain design. It means deliberate elimination of unnecessary elements.

Design discipline typically includes:

|

This approach improves longevity of style as well.

Durability Indicators Visible At Purchase

Experienced buyers often assess durability through visual cues:

| Indicator | Interpretation |

|---|---|

| Tight seam spacing | Higher tensile strength |

| Thick edge finishing | Wear resistance |

| Smooth hardware motion | Precision manufacturing |

| Consistent panel alignment | Accurate cutting |

| Even surface texture | Material stability |

These signals often predict lifespan better than brand names.

Aging Behavior And Long-Term Appearance

Accessories that look expensive tend to age predictably. Gradual softening, controlled patina, and stable color shifts indicate material integrity.

Rapid cracking, peeling coatings, or uneven fading reduce perceived value quickly. Long-term appearance stability reinforces initial premium impression.

Maintenance also affects aging. Proper cleaning, storage, and usage habits extend visual quality regardless of price category.

Bottom line

An accessory looks expensive when it feels intentional rather than decorative. Correct proportions make it practical to use, solid structure keeps it from sagging or warping, and precise finishing shows real manufacturing care.

Consistent materials, smooth hardware, clean edges, and balanced design usually matter more than logos or price. When an item holds its shape, ages evenly, and works comfortably in daily use, it naturally gives a premium impression.